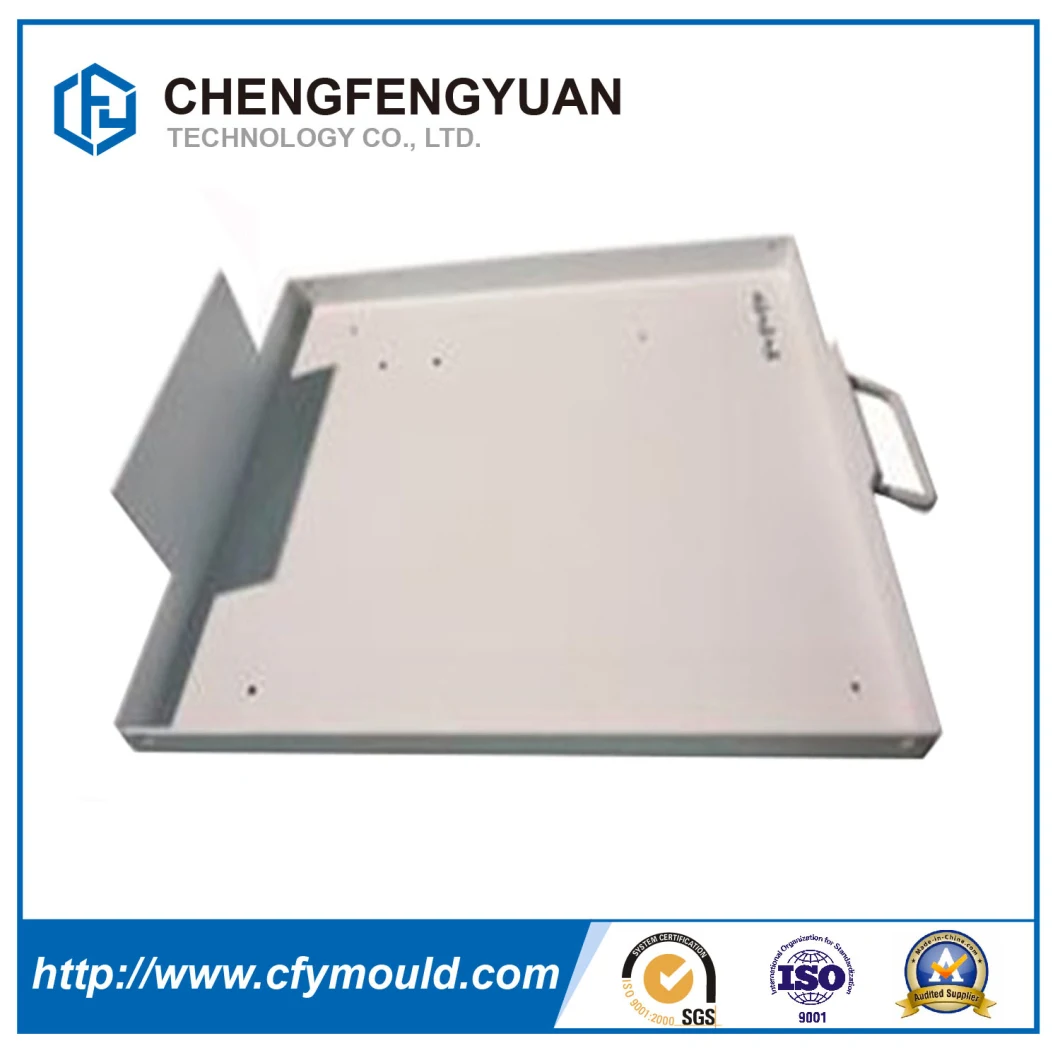

Manufacturing Process | Laser cutting,stamping, deep stamping,bending, punching, threading,welding, polishing,tapping,riveting,assembly. |

| Material | Stainless steel, carbon steel,copper,aluminium, brass, iron, and bronze (according to customer's requirements) |

| Surface Treatment | Galvanized(zinc-plated, nickel-plated,chrome-plated,silver-plated), powder coating, polishing(mirror polishing, electrolytic polishing), brushing,sand blasting,chemical etching,passivation treatment, etc. |

| Tolerance | +/-0.01mm |

| Package | Plastic film+harden carton box+plywood case |

| Application | Auto parts,Food Machinery,medical testing and equipment, electronic products, electric appliance,power switches, miniature switches,A/V equipment. |

| Quality Control | Conducted by ISO9001 |

| Drawing File Format | Solidworks,Pro/E,,Auto CAD,PDF |

| Features | 1.Customized Design 2.Small Order Allowed 3.Sample Product Available 4.Competitive Price due to factory direct supply |

| Inspection | IQC,PQC,FQC,OQA |

Detail About CFY Technoly Co.,Ltd.

Chengfengyuan Technology Co., Ltd. (CFY), a wholly-owned enterprise and Chinese direct manufacturer, was founded in January 2008, The company has passed ISO9001: certification.

The company mainly produces sheet metal, plastic injection mould, power cabinet, chassis, cabinets, network cabinets, advertising cabinets, computers, die casting, communications and other products supporting hardware, assembly, etc. We have also R&D of metal mould design and manufacturing, as well as various types of metal stamping parts, LED frame, rear shell, metal base.

Packing and Shipping

FAQ

1. Are you manufacturer or trade Company?

We are a factory founded in 2008 with trade team for international service.

2. What terms of payment you usually use?

T/T 30% deposit and 70% against document, Western Union, L/C at sight

3. What is your lead time for your goods?

Normally 35 days after confirmed order. 30 days could be available in low season for some items (during May to July), and 45 days during new year and hot season ( Jan to March).

4. Samples

For customers who need sample confirmation before ordering, please bear in mind that the following policy will be adopted:

1) All samples are free of charge with the maximum value not exceeding USD 100.

2) The courier cost for the first-time sample sending will be charged for by the consignee. We will send the samples with freight to be collected. So please inform your account with FedEx, UPS, DHL or TNT so that we can proceed promptly.

3) The first-time courier cost will be totally deducted from the contract value of the trial cooperation.

5. Order Process

| 1.Sample/Drawing | We need your detail require clearly. |

| ↓ | |

| 2.Negotiation | Material,cavity,price,delivery time,payment term ,etc. |

| ↓ | |

| 3.Place order | According your own design or choice our design. |

| ↓ | |

| 4.Mould design | We will communicate&Exchange the opinion with you during making drawing |

| ↓ | |

| 5.Tooling mould | After custome approve the mould design will start making mould. |

| ↓ | |

| 6.Mould process | Provide photos for customer show them tooling process |

| ↓ | |

| 7.Sample confirm | Send you sample for confoirm it ,if not satisfied by customer.we modify mould . |

| ↓ | |

| 8.Delivery mould | Delivery mould after customer approve sample and arrange shipment. |